Megha Thakur 2025-10-10

Think about that old pressure cooker at home, the one that’s survived countless meals and still seals tight despite all the steam, heat, and pressure, or those running shoes that keep their bounce even after years of use. Even the cables that power our homes and machines, staying flexible and strong through everything. What keeps them all going isn’t luck, it’s the smart molecular design built through advanced crosslinking technology.

The molecular foundation: Understanding polymer networks

At the molecular level, polymer chains exist as long, flexible strands. Left alone, these strands can move past one another, which allows flexibility but also leaves the material vulnerable: it can deform permanently under load, lose shape when heated, or break down under chemical exposure. The game-changer is cross-linking.

By forming chemical bonds between individual polymer chains, you create a three-dimensional network structure. That process turns loose, flowing polymer chains into a tightly connected network, a structure strong enough to handle stress, heat, and even harsh chemicals without losing its shape or strength.

The evolution of cross-linking: From peroxide to performance

For decades, organic peroxides, such as dicumyl peroxide (DCP) have been the standard cross-linking agents in elastomers and thermoplastics. When heated, these compounds break down and release highly reactive free radicals. Those radicals pull hydrogen atoms from the polymer chains, and the resulting polymer fragments join together to form strong carbon–carbon bonds. These carbon-carbon bonds offer enhanced thermal stability and resistance to oxidative aging compared to older sulphur-based vulcanisation systems but formulators recognised limitations: volatile by-products, odour issues, blooming (migration of additives to the surface), longer cure times and limits on how dense the networks could be.

Enter TAIC: Boosting Cross-Linking Efficiency

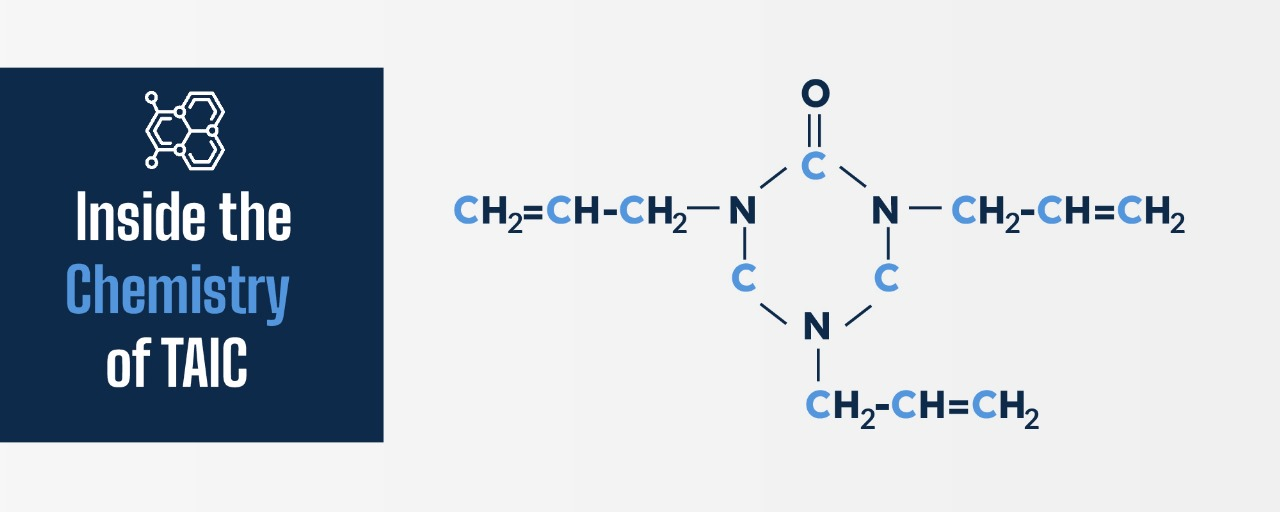

Triallyl Isocyanurate, or TAIC, brings a major upgrade to how cross-linking works. It’s a multifunctional co-agent made up of three reactive allyl groups connected to a strong, heat-resistant triazine ring.

When used with peroxide systems, TAIC helps the reaction move faster and build a stronger network. The peroxide starts the process by creating polymer radicals, and TAIC’s allyl groups offer extra bonding points that attach to these chains. Each TAIC molecule acts like a tiny hub, linking multiple chains together and tightening the entire structure, all without needing extra peroxide.

Performance advantages: Measurable improvements

Using TAIC delivers clear performance improvements.

Economic intelligence: Maximum impact at minimal dosage

Not only does TAIC deliver high performance, it does so economically. Typical formulation levels of peroxide might be around 1 phr (parts per hundred rubber). TAIC, as a co-agent, might be used at 10% of the peroxide level, so around 0.1 phr of TAIC.

Standard dosage ranges from 0.5 to 4 phr depending on the compound and application, because you get much higher cross-link density per peroxide molecule, formulators can reduce peroxide levels, avoid excessive by-products and minimise surface migration issues.

This makes TAIC a cost-effective route to higher performing materials.

Industrial Applications

The benefits above translate into many real-world applications:

Storage and Handling: Maintaining Product Quality

While TAIC is highly useful, proper storage and handling matter. The compound is often supplied as a crystalline solid or viscous liquid, with a melting point around 24-27 °C. Key handling guidelines include:

The Chemistry: A Closer Look

When a TAIC-containing compound is heated above the peroxide’s decomposition temperature, peroxide molecules cleave homolytically into radicals. These radicals extract hydrogen atoms from polymer chains, creating polymer radicals.

In a typical peroxide-only system, polymer radicals recombine, forming cross-links. With TAIC present, however, the polymer radicals can react with TAIC’s allyl groups, grafting TAIC molecules onto polymer chains. Once tethered, those TAIC molecules provide extra allyl groups for further cross-links. Some TAIC may even homopolymerise into short oligomers that integrate into the network.

The result: a substantially higher cross-link density and network connectivity per unit of peroxide than would be feasible otherwise. The theoretical and experimental literature confirm that TAIC accelerates and multiplies cross-linking efficiency.

The strategic advantage for Rajshila

At Rajshila, with 40 years of experience and a product range exceeding 450 products serving over 30 industries, we understand materials performance is not just about chemistry, it’s about intelligent solutions. By partnering with co-agents like TAIC and premium rubber-and-compound systems, Rajshila empowers formulators to deliver higher durability, whether that’s a seal that holds through extreme automotive cycles, or a cable insulation that lasts decades under heat, flex and chemicals.

Our depth across industries means we provide tailored support: whether you need a high-temp gasket in aerospace or a flexible hose in renewable-energy equipment, we help you choose the right cross-link chemistry, optimise dosage and streamline processing. If you’re seeking materials that outperform in challenging conditions, contact Rajshila today.